zecojoy

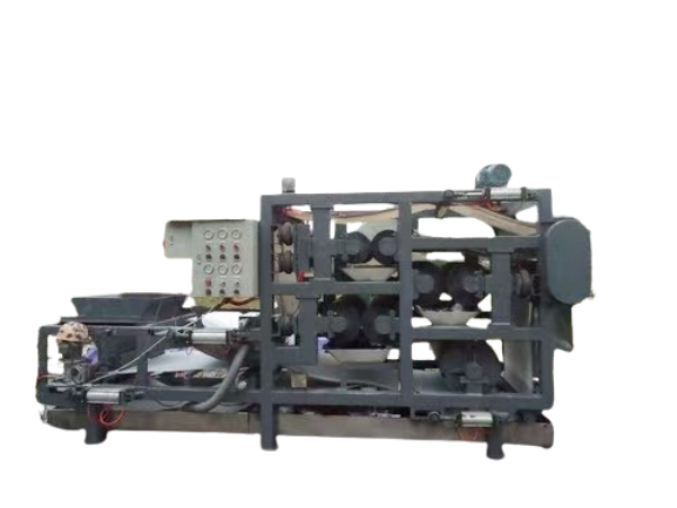

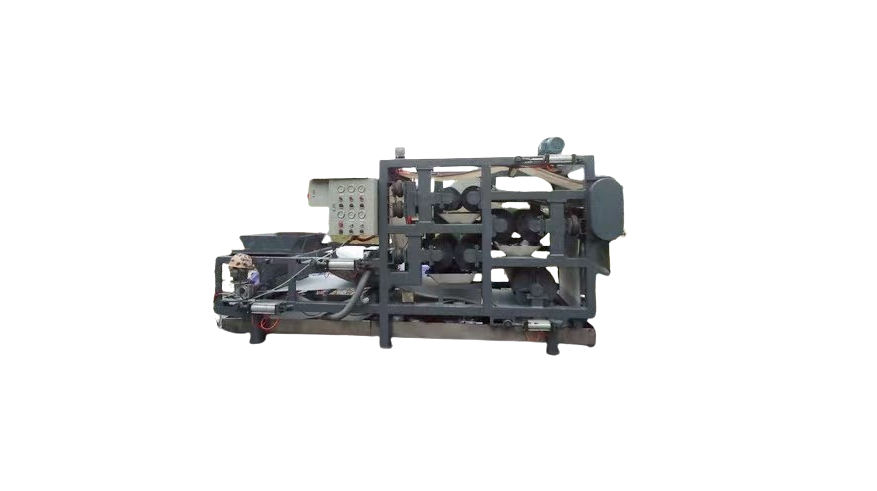

High Strength Double Roller Belt Press Dehydrator

High Strength Double Roller Belt Press Dehydrator

Ask for a quote below.

WhatsApp: 008613874781515

WhatsApp: 008613874781515

Email: postmaster@zecojoy.com

Email: postmaster@zecojoy.com

Functional Feature

The High-Torque Roller Belt Press is an efficient solid-liquid separation equipment, especially suitable for the dewatering treatment of high-moisture materials such as sludge and pomace. Here are the main functional features of this equipment:

High-Torque Roller Pressing: The equipment uses a high-torque roller for pressing, which can provide higher pressure, thereby achieving a lower cake moisture content.

Continuous Dewatering: The belt press dewatering machine can operate continuously for 24 hours, improving production efficiency and fitting well into continuous production processes.

High Processing Capacity: It has a large processing capacity, capable of handling 3-20 cubic meters of material per hour, suitable for large-scale sludge dewatering.

Automatic Control: The equipment is usually equipped with an automatic control system, which can realize functions such as automatic deviation correction and automatic flushing, reducing manual intervention.

Low Operating Costs: Due to low energy consumption and stable operation, the operating costs of the High-Torque Roller Belt Press are low.

High Dewatering Efficiency: It can reduce the moisture content of sludge from 85%-95% to 50%-60%, greatly reducing the burden on subsequent drying equipment.

Compact Structure: The equipment has a compact structure, taking up little space, which is convenient for installation and layout.

Easy Maintenance: The design of the equipment considers the convenience of maintenance, making it easy to inspect and replace worn parts.

Filter Belt Adaptability: The appropriate filter belt can be selected according to the nature of different materials to meet different dewatering requirements.

Corrosion-Resistant Materials: Some parts are made of corrosion-resistant materials, enhancing the equipment's corrosion resistance.

High Solid Content Cake: The cake after pressing has a high solid content, which is beneficial for resource recovery and reducing disposal costs.

Reduced Drying Energy Consumption: Materials dewatered by this equipment can be directly fed into drying equipment, significantly reducing drying energy consumption.

Environmental Performance: Reducing the volume and weight of sludge is beneficial for environmental protection and reducing transportation costs.

Safety Performance: The equipment is equipped with necessary safety protective measures, such as emergency stop devices and overload protection.

The High-Torque Roller Belt Press, with its characteristics of efficiency, energy saving, and environmental protection, has been widely used in industries such as environmental protection, chemical, food, and brewing. Applications include:

It is widely used for dewatering pomace materials from the processing of plant roots, stems, leaves, and fruits, such as:

Wine lees

Beer lees

Coconut shell fibers

Horse hoof residue

Cassava residue

Sweet potato residue

Tea residue

Corn residue

Sugarcane residue

Chinese medicine residue

Apple residue

Soybean residue

Coffee residue

Wood pulp fibers

Paper pulp fibers, etc., for mechanical dewatering.

Main Specifications and Technical Parameter

| Technical Parameters | Model | ||||

| DYJ1000P3 | DYJ1500P3 | DYJ2000P3 | DYJ2500P3 | ||

| Power (KW) |

Host Machine | 4 | 5.5 | 7.5 | 11 |

| Concentrating Machine | 10 | 13 | 16 | 20 | |

| Filter belt width(MM) | 1000 | 1500 | 2000 | 2500 | |

| Processing capacity(M3/H) | 1000 | 1500 | 2000 | 2500 | |

| External Dimensions | Length(MM) | 5300 | 5300 | 5300 | 5300 |

| Width(MM) | 1900 | 2400 | 2900 | 3400 | |

| Height(MM) | 2500 | 2500 | 2600 | 2600 | |

| Total weight of the machine(KG) | 5000 | 6500 | 9000 | 11000 | |

| Slurry Moisture Content | 50-65% | ||||

Share